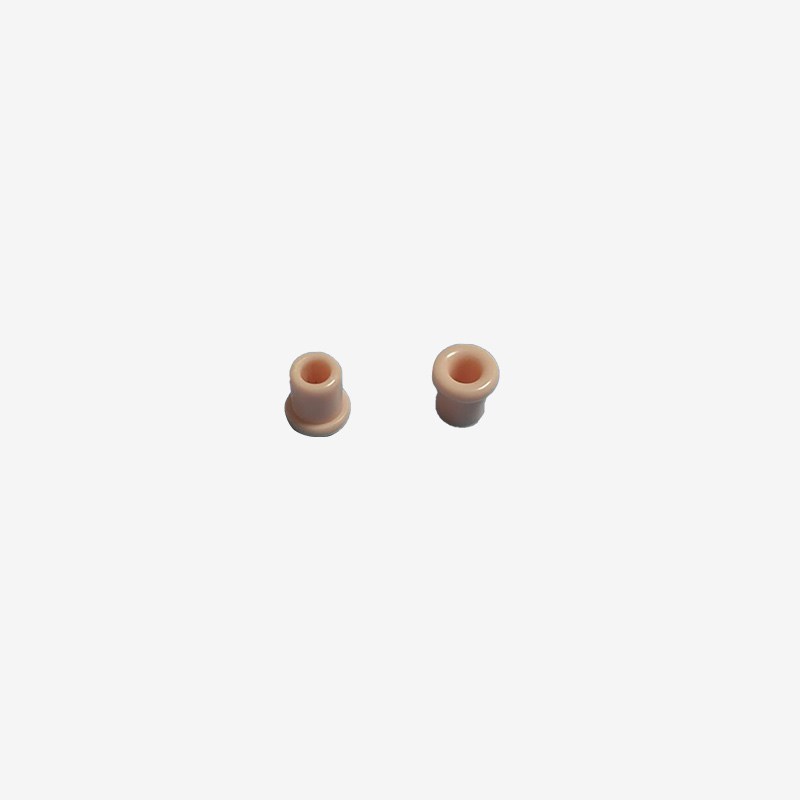

Alumina Ceramic Qaybta Mashiinnada Dharka

Goobta Codsiga

Qaybaha dhoobada dunta ah oo si weyn loogu isticmaalo mashiinnada dunta leh hantida farsamada sare, engegnaanta sare, xidhashada dheer, caabbinta dahaarka weyn, ka hortagga daxalka wanaagsan, heerkulka sare u adkaysta.

Qaybaha dhoobada duntu waxay leeyihiin codsiyo badan oo kala duwan oo nolol maalmeedka ah.Waxaan leenahay qaybaha ceramics almunia waxaa loo isticmaali karaa hababka sida isku dhafka dunta, sawiridda, laftirka, balaastiga, tolida, iyo tolida iyo wixii la mid ah.Shiinaha waa suuqa ugu weyn ee qaybaha dhoobada dharka.Intaa waxaa dheer, warshadaha agabka dhoobada dhoobada ah ee gudaha ee tartanka ku jira ayaa sidoo kale si joogto ah isbeddelaya.

Qaar ka mid ah ganacsiyada gudaha ayaa si tartiib tartiib ah u yareeyay farqiga u dhexeeya noocyada ajnabiga ah iyada oo loo marayo cilmi-baaris tignoolajiyadeed iyo horumarinta iyo horumarinta tayada, saamigooda suuquna si tartiib tartiib ah ayuu u kordhay.Isla mar ahaantaana, qaar ka mid ah noocyada ajnabiga ah ayaa si tartiib tartiib ah u soo galay suuqa Shiinaha, iyaga oo sii xoojinaya warshadaha qalabka dhoobada.

Faahfaahin

Shuruudaha tirada:1pc ilaa 1 milyan oo pcs.Ma jiro wax xaddidan oo MQQ ah.

Tusaalaha wakhtiga hogaaminta:qalab samayntu waa 15 maalmood+ muunad samaynaysa 15 maalmood.

Waqtiga hogaaminta wax soo saarka:15 ilaa 45 maalmood.

Muddada lacag bixinta:oo ay labada dhinac ka wadahadleen.

Habka wax soo saarka:

Alumina (AL2O3) dhoobada dhoobada ah waa dhoobo warshadeed kaas oo leh qallafsanaan sare, xidhid dheer, waxaana lagu samayn karaa oo kaliya shiida dheeman.Waxaa laga soo saaray bauxite waxaana lagu dhammeeyaa qaabaynta duritaanka, riixida, dareeraha, shiididda, farsamaynta iyo farsamaynta.

Xogta Jirka & Kiimikada

| Alumina Ceramic(AL2O3) Xaashida Tixraaca Dabeecada | |||||

| Qeexitaanka | unug | Fasalka A95% | Fasalka A97% | Fasalka A99% | Fasalka A99.7% |

| Cufnaanta | g/cm3 | 3.6 | 3.72 | 3.85 | 3.85 |

| Jilicsan | Mpa | 290 | 300 | 350 | 350 |

| Xoog cadaadis leh | Mpa | 3300 | 3400 | 3600 | 3600 |

| Hababka bartinimada | Gpa | 340 | 350 | 380 | 380 |

| Iska caabbinta saamaynta | Mpm1/2 | 3.9 | 4 | 5 | 5 |

| Weibull modules | M | 10 | 10 | 11 | 11 |

| Vickers hardulus | Hv0.5 | 1800 | 1850kii | 1900kii | 1900kii |

| Isku xidhka Balaadhinta kulaylka | 10-6k-1 | 5.0-8.3 | 5.0-8.3 | 5.4-8.3 | 5.4-8.3 |

| Dhaqdhaqaaqa kulaylka | W/Mk | 23 | 24 | 27 | 27 |

| Iska caabinta shoogga kulaylka | △T℃ | 250 | 250 | 270 | 270 |

| heerkulka isticmaalka ugu badan | ℃ | 1600 | 1600 | 1650 | 1650 |

| Iska caabinta mugga ee 20 ℃ | Ω | ≥1014 | ≥1014 | ≥1014 | ≥1014 |

| Awoodda korontada | KV/mm | 20 | 20 | 25 | 25 |

| Dielectric joogto ah | εr | 10 | 10 | 10 | 10 |

Baakad

Caadi ahaan waxaan u isticmaalnaa walxo ay ka mid yihiin kuwa aan qoyaanka ka ilaalin karin, shoogga-ilaalinta alaabooyinka aan waxyeello yeelan doonin.Waxaan isticmaalnaa bacda PP iyo kartoonnada alwaaxyada sida waafaqsan shuruudaha macmiilka.Ku haboon gaadiidka badda iyo hawada.